Leachate Collection Pump Stations

Leachate Collection Pump Stations

The collection, handling, and management of water runoff from landfill sites is one of the most important aspects of environmental responsibility. Leachate collection is carefully managed and controlled, and the storage of collected leachate, and pumping for transport or onsite treatment is critical infrastructure. Pump stations become as critical to the success of the landfill as anything.

Leachate is a liquid that is formed when rainwater percolates through landfill waste and typically contains high levels of organic and inorganic contaminants, including heavy metals and volatile organic compounds (VOCs). This liquid is often highly toxic and corrosive and poses a risk to the environment. As you can conclude, this makes it uniquely difficult to dispose of properly. That is where a leachate pump station design comes into play.HDPE Wet Wells

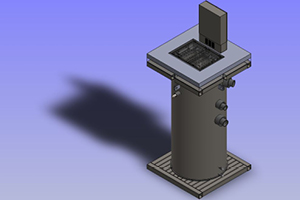

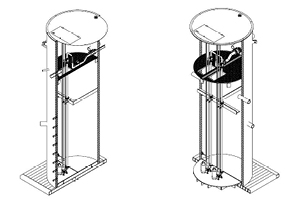

Leachate collection pump stations typically consist of a wet well, submersible pumps, mechanical components, piping, valves and a control panel. The most durable wet wells are manufactured using structural high-density polyethylene (HDPE), a thermoplastic material that is known for its proven chemical resistance and durability that blocks the corrosive effects of leachate. Without the need for any protective surface coatings, HDPE is resistant to chemical degradation, provides a long service life, and comes prepackaged as a monolithic structure to eliminate the risk of leaking. The submersible pumps are located within the wet well and used to pump the leachate to a transport vehicle or onsite treatment facility for safe neutralizing and disposal.

HDPE Structural Calculations

HDPE Structural Calculations

- Manufacturing Standards: ASTM F894

- Pipe Size: 18 in. to 132 in. I.D.

- Pipe Ring Stiffness: Up to 400

- Pipe Length: Up to 50 ft.

- Pressure Rating: Up to 30 PSI

- Pipe Connection: Welded or Flanged

- Flexural Modulus: 80,000 - 110,000 PSI

- Tensile Strengths: 3,000 - 5,000 PSI

- Certifications: NSF, BNQ

-

Friction Factor; Hazen-Williams / Manning: 150-155 / 0.01

Pump Station Installation Map

Pump Station Design Type

Wet Well Type

Application Type

Project Challenges Solved

Following are recent examples of Excel Fluid Group supplied leachate pump stations designed for maximum durability, design life and efficiency. To get more views of the projects check out the image gallery at the bottom of the page. Leachate is aggressive. The right equipment is critical. Let’s get it handled.

Loudoun County, VA – Leachate Pump Station

- 6 ft. diameter x 22 ft. deep HDPE pump station with 12 ft. x 9 ft. deep valve vault and odor control chemical tank

Bradford County, PA – Northern Tier Solid Waste Authority

- 8 ft. diameter by 26 ft. deep HDPE pump station with an internal 7 ft. deep valve vault and flow meter within

Adams County, PA – ADSCO Landfill Pump Station

- 5 ft. diameter x 13 ft. deep HDPE pump station with custom leak detection assembly

Munising, MI – Wood Island Landfill Pump Station

- 10 ft. diameter by 20ft. deep HDPE pump station with a 6ft. diameter double-walled liner and a 10 ft. x 8 ft. fiberglass controls building

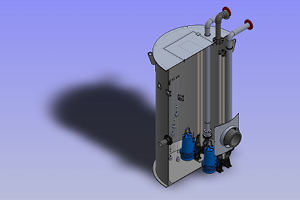

Jeffersonville, IN – Clark-Floyd Landfill Truck Loadout Pump Station

- Retrofit pump station reusing an existing on-grade storage tank designed to load tanker trucks in 15 minute intervals

Preble County, OH – Landfill Pump Station with a Concrete Building

- Prefabricated 10.5 ft. x 12.5ft concrete building outfitted with 2 in. HDPE piping for a duplex end-suction pump system

Polk County, FL – Landfill Fiberglass Pump Station

- 6 ft. diameter by 10 ft. deep fiberglass pump station with 4 in. Schedule 80 PVC piping

We hope this helps give you a better understanding of how we execute Leachate pump stations. To get further information on HDPE pump stations, check our HDPE vs. Concrete Pump Station design and Which Pump Station Design is Right for You? blog posts. If you have any questions about your next pump station design, contact us today!