Frequently Asked Pump Station Maintenance Questions

Frequently Asked Pump Station Maintenance Questions

Once a pump station has been designed, built, and installed to your requirements, maintaining an efficient, operational system is the goal. As a trusted partner throughout the design and build processes, maintaining your lift station is a critical contributor to a successful system. It doesn’t matter if you have a fleet of pump stations or you are focused on a single system, we have you covered from our 30+ years of pumps and pump station experience. We design all our pump stations with longevity in mind but there are also some tips and tricks you can use to aid your station’s lifespan. Whether it’s your team performing the maintenance, or you ask us to help with preventative measures, check out some of the most common questions we get on how to keep your lift station up and running as you need it.

Pump Station Longevity

How long should a submersible pump or pump station last?

How long should a submersible pump or pump station last?

Pump stations are commonly designed to have a 50-year life span, and if a high-density polyethylene (HDPE) or polymer concrete wet well is used, then a 100-year design life is achievable. That said, a submersible pump spends its life in a tough environment and like other mechanical equipment is subject to wear and failure. A common life span of a submersible pump is 15-20 years.

How can I prolong the life of my pump station?

Regular preventative maintenance of any pump station is required to prolong the service life and ensure optimal performance. Service items could include removing debris from wet wells, cleaning interior of wet wells and piping to minimize corrosion, exercising valves, and performing electrical checks on the pumps and switchgear.

How much does maintenance cost for the owner, operator, or customer on a typical pump station per year?

Maintenance cost and requirements can vary based on the pump station type and age. As with any infrastructure, additional wear and failures can happen with age and have a direct impact on your pump station maintenance budget. Additionally, ongoing pump station expenses that impact every pump station include electrical consumption and service personnel wages. A good rule of thumb when planning annual maintenance costs is to budget $3,000 to $5,000 per month. This will provide ample funds if a pump, valve, or electrical switchgear needs to be replaced or upgraded.

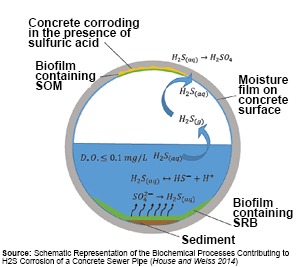

How can I prevent H2S Corrosion in my pump station?

H2S Corrosion can be detrimental to any concrete wastewater pump station. While you can apply paint, epoxy, or polyurea coatings inside your concrete wet well, we recommend changing the wet well material all together. HDPE (high density polyethylene) is inert to H2S all together and has a 100 year design life against harsh conditions. We typically see fiberglass wet wells in commercial lift station applications. These have about half the design life as HDPE but similarly don’t require any additional coatings. Lastly, polymer concrete wet wells are twice as strong as regular concrete but can't be pre-assembled prior to its arrival at the installation site. Being nonporous and consistent throughout the structure helps it protect against H2S more efficiently than a typical cement mixture.

H2S Corrosion can be detrimental to any concrete wastewater pump station. While you can apply paint, epoxy, or polyurea coatings inside your concrete wet well, we recommend changing the wet well material all together. HDPE (high density polyethylene) is inert to H2S all together and has a 100 year design life against harsh conditions. We typically see fiberglass wet wells in commercial lift station applications. These have about half the design life as HDPE but similarly don’t require any additional coatings. Lastly, polymer concrete wet wells are twice as strong as regular concrete but can't be pre-assembled prior to its arrival at the installation site. Being nonporous and consistent throughout the structure helps it protect against H2S more efficiently than a typical cement mixture.

What is the best way to avoid Arc Flash Hazards?

According to OSHA, there are 10 arc flash incidents every day in the United States that total more than 3,600 disabling electrical contract injuries each year. To prevent an arc flash, it is recommended that you deenergize the high voltage electrical components, wear suitable personal protective equipment (PPE), keep at a safe distance, then carry out a risk assessment. Our ArcSentry™ control panel design was built with safety in mind. On the outside of the panel, a panel hood protects the controls from the elements, there are pump disconnects for each individual pump, and there are convenience GFCI outlets available for tools. On the inside, the high voltage motor control cabinet is separated from the low voltage and SCADA elements. An electrical mechanical interlock will only allow access to the high voltage side of the panel when the control panel is powered off. This allows maintenance personnel to work on lower risk low voltage components while staying safe from the high voltage mechanisms.

Pump Station Maintenance

How often should we get our wet well vacuumed out?

Depending on your pump station application, we recommend fully vacuuming out your pump station every 6 months. Some stations can be worse than others though, like if your station has a known ragging issue (whether it be flushable wipes, fats oils and greases [FOGs], etc.). This helps with the longevity of pumps as it naturally provides better level controls because FOGs and debris should be forcibly cleaned out and not travelled through the system. Additionally, with a clean wet well you’ll get less false alarms, odor, and build up in general. Also, when it’s vacuumed clean, it’s a good time to do a visual check and take inventory of your complete station. It’s the perfect time to get everything for a complete wellness check.

Depending on your pump station application, we recommend fully vacuuming out your pump station every 6 months. Some stations can be worse than others though, like if your station has a known ragging issue (whether it be flushable wipes, fats oils and greases [FOGs], etc.). This helps with the longevity of pumps as it naturally provides better level controls because FOGs and debris should be forcibly cleaned out and not travelled through the system. Additionally, with a clean wet well you’ll get less false alarms, odor, and build up in general. Also, when it’s vacuumed clean, it’s a good time to do a visual check and take inventory of your complete station. It’s the perfect time to get everything for a complete wellness check.

Do we need to change the oil on our submersible Barnes pumps?

If the pump motor overheats, if there is a seal failure, or if it’s been over 10 years, we recommend changing the oils in your pump. Like with a lot of pump station maintenance, it doubles as a good time to check other surrounding components. This time we advocate checking the wear and tear on your bearings for metal shavings, if there’s water in the pump from a seal breach, or if there’s the smell of oil burning.

I don’t believe my transducer is reading right, how do I adjust it?

Having a transducer accurately measuring wet well levels can be key to preventing a pump from running overtime. To ensure it’s reading correct first pull the transducer from the wet well and clean it while inspecting it for any damage. Once that is done, check the pressure rating (this should be stamped on the body) and make sure it’s scaled properly in the control panel. The pressure rating is commonly scaled in either inches or PSI. If these are all appropriate, check your transducer off set, or how far the transducer is off the floor of the wet well, and validate that it matches in the control panel PLC.

Having a transducer accurately measuring wet well levels can be key to preventing a pump from running overtime. To ensure it’s reading correct first pull the transducer from the wet well and clean it while inspecting it for any damage. Once that is done, check the pressure rating (this should be stamped on the body) and make sure it’s scaled properly in the control panel. The pressure rating is commonly scaled in either inches or PSI. If these are all appropriate, check your transducer off set, or how far the transducer is off the floor of the wet well, and validate that it matches in the control panel PLC.

How do I fix a seal fail light alarm?

To fix a seal failure, you must change the oil in your pump. If there is a seal failure, the oil in a submersible pump is contaminated with wastewater from the wet well. In the case of a Barnes submersible pump, pull the pump and send it to a Barnes Warranty Center (Excel Fluid Group is a registered Barnes Warranty Center). Most Barnes submersible pumps have two mechanical seals so when the lower seal fails, that gives us time to catch it before it passes the second seal and reaches the pump motor. However, while your control panel will still allow for your pump to run after an initial seal fail, we recommend getting it to a Warranty Center as soon as possible. If the pump motor oil gets tarnished, you’ll need an entirely new pump motor and more than likely a new pump all together.

How do I fix a pump over temp alarm?

How do I fix a pump over temp alarm?

Like a seal fail, if your pump is overheating, we suggest first checking the volute is free of obstruction. If it was clogged, clean it out and monitor the running temperature over the next few days. If there was no visible clog, the pump should be sent to a Barnes Warranty Center as soon as possible. Unlike with a seal failure, most control panels will not allow a pump to run in the event of an over temp because there is a risk of fire.

How do I choose which service level is appropriate?

To determine how often to service your pump station you should first confirm how busy your pump station is. We recommend a quarterly in depth inspection for any influent type of station at a wastewater treatment plant or a station handling an entire residential neighborhood. In general base your service level on the pump station’s general designed flow per day or pump run hours. If your pumps are running 4-5 hours per day, a quarterly deep clean is appropriate while on stations that run 1-3 hours per day, twice a year should be plenty. Lastly, if it’s a residential pump station for a single home that only runs once a week, a yearly inspection should suffice.

Excel Maintenance

Can Excel maintain my station for me?

If it’s difficult for you and your team to remember to complete your regular pump station maintenance, have peace of mind with our Maintenance Plus plan. Depending on your plan, we will complete a full service on your pump system annually, semi-annually, or quarterly. If anything goes wrong with your pump, we have the resources to repair, replace, or maintain your pump station for seamless downtime and ideal upkeep. You can trust that we stand behind out products and are your best option to maintain what we design and build.

Do you offer field service?

Do you offer field service?

Yes, our pump station preventative maintenance checks include seal and overhaul kits with a detailed pump station electronic inspection report, clean and check the level or operations of the control, run pump down tests for each pump and record the level drop, and more.

What is Excel's Factory Warranty Process?

In the event of a warranty issue, please contact Excel Fluid Group to figure out next steps. By default, our enclosures are warrantied for 24 months from the date of shipment. All equipment, apparatuses, and parts furnished are under a 12 month warranty from their dates of shipment or to the manufacture 's specific warranty. In the event that a pump needs to be inspected further than what’s capable on site, we recommend sending the pump into our Warranty Center. For mechanical or electrical failures under warranty, Excel Fluid Group can visit the job site for a complete inspection. To learn more, see on our standard equipment warranty and responsibility statement here.

What geographical territory does EFG service?

While based in Cleveland OH, we are available to service anywhere in the continental United States. We will work with you to get your pump station maintenance in a timely manner. However, we will not perform emergency service. We focus on planned and calculated maintenance that reduces overall downtime and keeps your pump station fleet working and as modern as possible.

We hope this helps give you a better understanding of what the Excel Maintenance Experience is and where Excel Fluid Group can benefit your pump station fleets. This is part three of our four part FAQ series. Check out our Answering Your Pump Station Design Questions and Answering Your Pump Station Build Questions blog posts to see the previously two parts. If you have any questions about maintaining your pump stations, contact us today!