Why Use the ArcSentry™ Control Panel

Why Use the ArcSentry™ Control Panel

Safety is our number one priority. When working with pump stations constantly pumping water and wastewater it is very important to be aware of the electrical power used to run the application and safely minimize the user’s risk. That is why at Excel Fluid Group, we have worked with municipalities all throughout North America to develop the ArcSentry™ Control Panel. It provides a well-designed, intrinsically safe panel where maintenance can only be performed in the most dangerous areas when the compartment’s power is off. This prevents Arc-Flash electrical hazards as high and low voltage components are separated. We will take you through how the ArcSentry control panel works in a NoVault, what is a part of the high voltage compartment, and how the low voltage compartment allows, safe ease of access to alerts and troubleshooting.

Used in a NoVault™ Pump Station

The NoVault pump station allows for a smaller overall footprint with the controls and piping in an enclosure as small as a 3 ft. by 4 ft. When the ArcSentry is used in a NoVault application, the outside of the panel is protected from the elements by the NoVault’s gullwing doors. With that, the high and low voltage compartments are separate to reduce the risk of injury. Additionally, there is a pump disconnect for each individual pump and a convenience GFGI outlet safe on the outside of the panel. On the inside of the panel, we have segmented the high and low voltage motor control cabinets with the low voltage having optional SCADA capabilities for ease of use. SCADA and most other detailed alerts are easily programmed and communicated on the simple Pump Vision™ controller.

High Voltage Compartment

The ArcSentry high voltage compartment is only accessible if the power to the panel is turned off. This is done with an electrical and mechanical interlock that automatically lock the high voltage motor control cabinet while the panel is energized. Once power is disconnected maintenance can be done to high voltage components like the variable frequency drives (VFDs) or NEMA starters, pump disconnects, terminals, and circuit breakers. By allowing for only work to be completed while power is off, this give the maintenance team peace of mind that power is disconnected while work is being done.

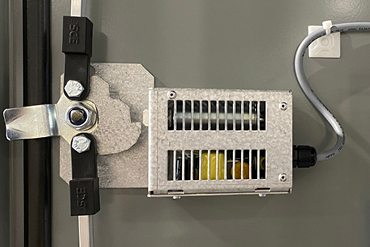

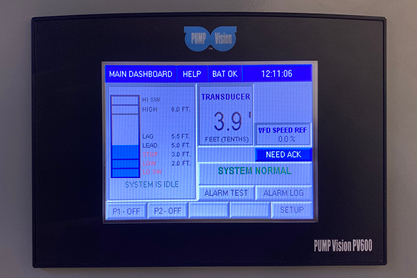

Low Voltage Compartment

With the low voltage elements separated in the control panel, this helps the end user quickly and easily diagnose what is available to work on while the power is on. The low voltage side houses the float and seal fail relays, power supplies, terminal strip for field connections, and intrinsically safe barriers and connections. Additionally, the CM Controls Pump Vision™ HMI will show the pump station levels, flow monitoring, VFD speed, control alarms, maintenance alerts, and more.

We hope this helps give you a complete overview of the ArcSentry™ control panel, built with safety in mind. We also offer tips on pump station controls and remote monitoring with Pump Vision™ and how to decide what emergency power supply is right for your pump station. If you have any questions on your pump station controls, contact us today!