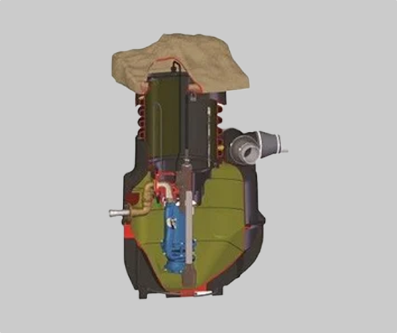

Barnes has invested heavily in innovation and cutting-edge pump solutions that integrate perfectly with EFG pump stations and provide excellent replacement options to existing underperforming pumps in service. One of Barnes’ latest products, the SITHE chopper pump, is handling the most difficult clogging issues we have seen. Where others fail, the SITHE cuts through. In a world where solid content in waste streams is increasing, the SITHE is the masterstroke against clogging.

.jpg)

.png)

.png)

.png)

.png)

.png)

Silver Spring, MD

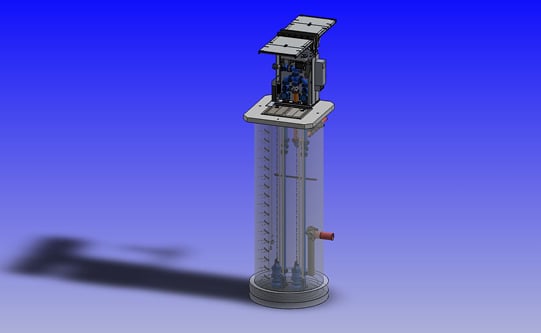

For their state-of-the-art hospital at White Oak Science Gateway, Washington Adventist Hospital and Soltesz Inc. chose an Excel Fluid Group pump station with features like a fiberglass wet well and Barnes Sithe chopper pumps, ensuring compliance with WSSC standards and enhancing bioscience and healthcare innovation in Montgomery County, Maryland.

.jpg)

Joint Base Andrews, MD

At Joint Base Andrews, Excel Fluid Group installed a compact NV2 NoVault pump station with explosion-proof Barnes BLADE grinder pumps and an HDPE wet well for the new firing range, integrating seamlessly with existing infrastructure while ensuring quick installation and minimal on-site disruption.

North Bend, OH

To upgrade the outdated system at North Bend Nitrogen Facility, Albertz Engineering and Lemm Corp chose an Excel Fluid Group pump station with a polymer concrete top and Barnes Sithe chopper pumps, ensuring clog-free operation and addressing confined space concerns with an easily accessible NoVault design.

.jpg)

5350 WEST 137TH STREET

BROOK PARK, OH 44142

© 2025 Excel Fluid Group • Design Creative Media