.png)

.png)

.png)

Dayton, OH

For Dayton’s industrial growth along Successful Way, the City and Sunesis Construction chose Excel Fluid Group’s prefabricated steel building and HDPE wet well with Barnes Sithe chopper pumps, ensuring efficient sanitary lift station operation and eliminating confined space and corrosion concerns.

Beaver, PA

For a new 150-lot Ryan Homes development in Beaver, PA, a custom sanitary pump station was designed with Sheffler & Company, featuring an insulated fiberglass enclosure, HDPE wet well, odor control measures, and emergency power backup.

.jpg)

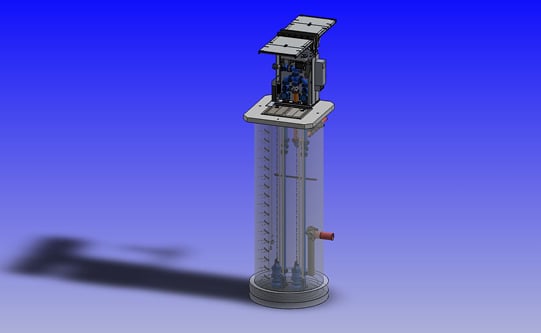

Joint Base Andrews, MD

At Joint Base Andrews, Excel Fluid Group installed a compact NV2 NoVault pump station with explosion-proof Barnes BLADE grinder pumps and an HDPE wet well for the new firing range, integrating seamlessly with existing infrastructure while ensuring quick installation and minimal on-site disruption

.jpg)

5350 WEST 137TH STREET

BROOK PARK, OH 44142

© 2025 Excel Fluid Group • Design Creative Media