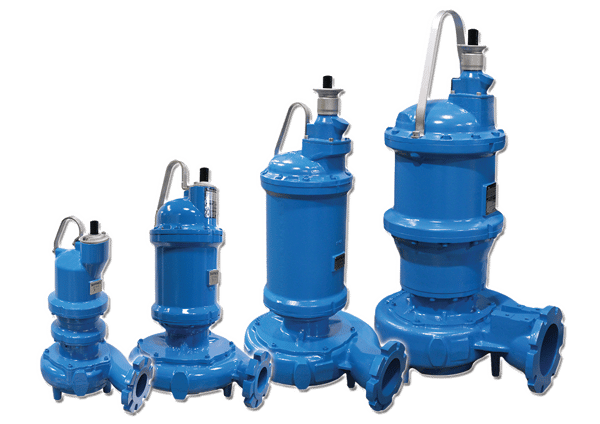

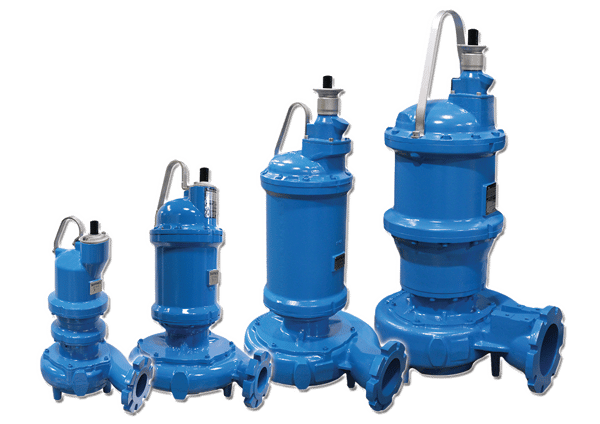

Excel Fluid Group has extensive working knowledge of non-clog submersible pumps. Working with Barnes, ABS, Goulds, Myers and other brands, we can select the correct pump for your application. Our expertise and experience with municipal sewage lift stations, wastewater treatment plants and industrial applications means that you will get the right pump for what you need – every time.

We have hundreds of non-clog submersible pumps in stock. If you need to upgrade your current pump, we’ll help you get it done without dealing with long lead times.

Shop Barnes Non-Clog Pumps at the Excel Pump Warehouse

Barnes SH Series Pumps

SH submersible solids handling impellers are designed for outstanding clogging resistance and true pumping efficiency. These wet-well submersible pumps utilize a combination of inverter-duty rated motors, ideal for variable speed operations and an external coating system providing corrosion resistance. Additionally, SH Series pumps are:

- Designed for Solids Handling With Less Clogging

- SH utilizes vortex, monovane or dual or tri-vane impellers

- Minimum 3″ spherical solids handling capability on most pumps (2 ½” on 3 SHMP)

- Pump-out vanes protect the mechanical seal area

- Designed for Variable Frequency Drive

- Inverter-duty rated motors per NEMA MG1 Part 31 for dependable VFD operation

- Designed for Longer Mechanical Seal Life

- Grit-resistant silicon carbide or tungsten carbide pump-end seal faces

- Heavy shaft design to minimize deflection

- Standard, non-proprietary seals – readily available

- Designed for Longer Bearing Life

- Heavy-duty shaft reduces deflection loads

- Oil lubrication provides superior life compared to grease

- Bearing ratings of 50,000 hours at minimum flow (2.0 fps)

- Designed for Tough Wet Well Environments

- SH uses components and coating systems to provide outstanding corrosion resistance

- Two coats of DuPont Corlar® modified polyamide epoxy provides outstanding external corrosion protection

- Pump shaft, all fasteners and the large lifting bail are corrosion-resistant stainless steel for long life

The ABS EffeX Range

The World’s First Premium Efficiency Submersible Sewage Pumps!

The ABS EffeX range of submersible sewage pumps offers you a complete solution for your pumping needs. It does this by a combination of much-improved reliability, greater energy savings, the highest level of clog resistance, future-proof design and a clear commitment to achieving the highest sustainability in both manufacturing and operation. Simply put, we now give you greater peace of mind in running your wastewater business.

The ABS EffeX range will virtually cover all submersible sewage pump applications in the following segments: wastewater collection networks, wastewater treatment and domestic and commercial wastewater.

Premium Efficiency and a Lot More

A premium-efficiency motor is just one of many benefits you get with the ABS EffeX range. After analyzing market needs and the design of our ABS submersible wastewater pumps, we have built in a number of new features that make our ABS EffeX range the best pumps available, including:

Long-term reliability

- Reduced risk of pollution from overflows

- Reduced risk of interruption to services for customers

- Reduced breakdown costs

- Reduced sump cleaning costs

- Reduced maintenance costs

Greater energy savings

- Reduced energy costs

- Smaller CO2 footprint

- Qualification for capital allowance funds

Excellent rag handling

- Reduced risk of pollution from overflows

- Reduced risk of interruption

- Reduced breakdown costs

- Reduced sump cleaning costs

Future-proof design

- Compliance with planned EU, USA, CAN and other legislation for conventional motors

- Impeller designs based on future wastewater content

- High reliability to ensure compliance with overflow reduction targets

Sustainable in manufacturing and operation

- Reduced CO2 emissions in pump manufacturing and operation

- Increased pump life

- Reduced maintenance costs by field adjustments rather than in-house repair

Resources

PDF – Barnes SH

PDF – Barnes Flyer

PDF – ABS EffeX